I work with a lot of suppliers, but this order has stood out from the very first email. Although I had not dealt with your company before, the service has been truly world class. From a clear and helpful quotation with advice on the correct service pack to a swift delivery estimate, everything was well communicated.

I was delighted when the order arrived four days earlier than expected. When a critical part has failed and there is no spare in stock, that makes a huge difference. Your fast turnaround allowed our maintenance team to resolve the issue far quicker than planned.

Thank you for the outstanding service!

Annette Taylor, Major International Bread Producer

I just wanted to say thank you for the help and support you recently provided on a very urgent enquiry.

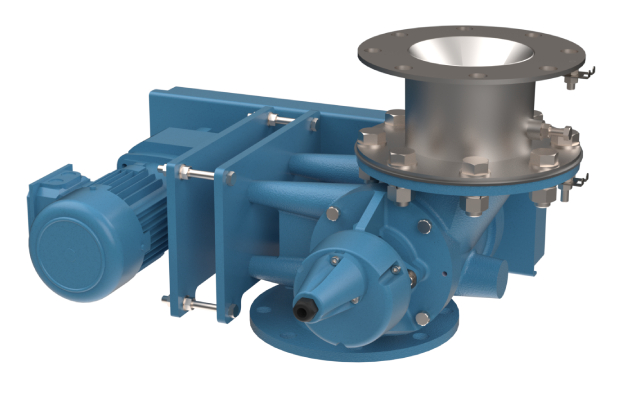

One of my customers needed a rotary valve manufactured and delivered within just a few days. After considering my options, I reached out to Rotolok with the drawing and specification. From the very first response to my enquiry, it was clear the team genuinely wanted to help. Communication was quick and professional, and the order was placed with a delivery target of early the following week.

When I followed up on the Monday, I was impressed to hear the valve had already been built and was out for delivery the next day. The customer service and turnaround time were outstanding. Please pass on my thanks to everyone involved – they’re a credit to your business.

Steven Rought, On Site Manager, Hayley Birmingham

"I wanted to congratulate the entire team at Rotolok on the initial sales consultation, after sales support, technical documentation and most importantly the quality and reliability of your finished product. Notably the two ATEX certified rotary valves we bought from you last year have been faultless!"

Rob Rogers, Technical Director, Gough Engineering

"You delivered the first 2 rotary valves in around 3 weeks, which was not only 1 week sooner than you quoted me, but an impressive 17 weeks faster than I was quoted by a competitor of yours!!”

Richard Stanton, RAS Extraction Ltd

“I would like to take this opportunity to express my thanks to every staff member at Rotolok for their sincere support throughout. I would definitely recommend Rotolok to be considered on our future projects where advice is sought”

Mechanical Engineer, Multi-National Project Management Consultancy

"We have been working with Rotolok for many years, throughout we have been overwhelmed with the product quality and especially the communication."

General Manager, Major OEM Supplier, Lithuania

"Can you pass our thanks and appreciation to everyone involved with the delivery improvements on the unit delivered today. I know we put you all under some pressure, but you accepted the challenge and delivered upon it. Thank you for your fantastic service, we are all very grateful!"

Russell Horrigan, Hayley Group Ltd

“The RotoFlex Valves arrived today and I could not be happier with them!”

James Saker, Maintenance Technician at DDW, The Color House

“You may not know this but I bought twenty 250 drop through seals from Dan McCauley when he first started up in the mid to late 70’s. I think I picked them up from his home near Gatwick- they are still running perfectly!!”

Duncan Marston, Former Director at C Marston and Sons (Now known as Heygates, Icklingham)

"Thank you so much for the prompt response and great support as always!”

Multinational Consumer Goods Manufacturer

"I was really happy about the service and the fast responses I received.”

Mischa Ruf, Process Engineer, Ingelia

"The specification was exactly as ordered and the Rotolok valve worked very well in every moment of production. We appreciate the interest to deliver the perfect product for our application."

Alessandro Gonzalez, Mechanical Designer, IRIS S.R.L, Italy